Become a successful automation engineer

Learn Advanced Industrial Automation customized as per your need

Key concepts to be covered in the course

- Automation Project documentation

- Field instrumentation

- Electrical basic and drawings

- PLC hardware

- PLC software and communication

- SCADA | HMI

Course Details

The course covers all the components of Industrial Automation from fundamentals to advanced programming which makes the candidate suitable for the changing requirements of the industry. Complete modules can be customized as per your requirement

Key Features

Mock Interviews

CV Preparation

Hands on Experience

Who is this course for?

- Engineering Students

- Working Engineers

- Diploma Holders

Course Details

Content

Students can select any modules as per their requirement

- Field —PLC—Field Concept understanding.

- Basic Difference between DI and AI and Application of It

- Basic of Process Instrumentation

- Pressure – PS, PT, PG : Working principle, MOC, Selection Criteion, Sensing Elecments,Output Signals

- Level – LS, LT, LG:Working principle, MOC, Selection Criteion, Sensing Elecments,Output Signals

- Flow – FS, FT, FG:Working principle, MOC, Selection Criteion, Sensing Elecments,Output Signals

- Temperature- TT, TS, TG:Working principle, MOC, Selection Criteion, Sensing Elecments,Output Signals

- SV, Pump, Actuators etc

- Control Valve Types & Application

- Control Loops in Process Automation

- Type of Transmitter and it wiring details

- P & ID,PDS document for Instrumentation Engineering Activities, Importance and Application

- Instrument List & I/O Assignment for actual PPM

- Hook-up & Tray Routine Drawing tracing on PPM

- Instrument Datasheet- Reading of various datasheet installed in plant

- PLC/DCS Wiring Drawing- Checking on Panel

- Junction Box(JB) Scheduling & Grouping, Cable schedule- Loop checking on PPM

- Relay Wiring, with practice

- Basic of Electrical System in Industry

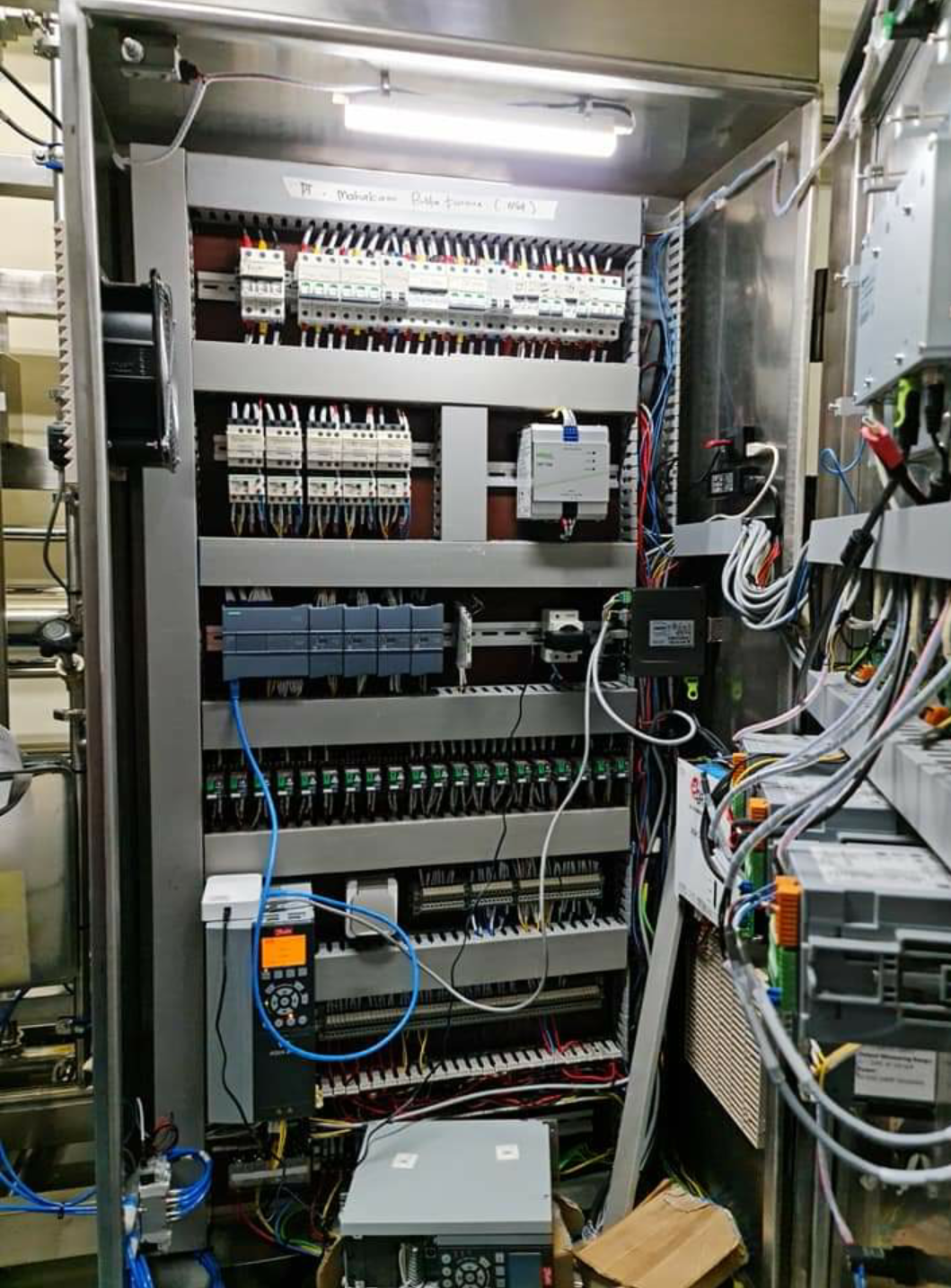

- MCC/PLC Panel

- Power & Control Wiring- DI/DO, AI/AO wiring

- Pushbuttons,Motors,Cables in Electrical System

- Earthing Systems-Power earth,signal earth,Earthing Grid & Pit

- FAT procedure on Control Panel: Loop checking

- Signal measurement on Multimeter – Current, Voltage on PPM

- Wiring Contuinity test on Panel- Siemens

- Field- PLC-Field Signal flow concept understaning

- Basic difference between DI and AI

- History of automation,PLC Hardware with Introduction

- Fundamentals of PLC Logic Development Software

- PLC Rules With NO,NC,COIL Concept

- PLC Network & Data Communication

- Sink & Source Concept,Relay

- Bus systems,Scan Cycle,Scan Time

- Introduction to PLC Software

- Ladder Logic Concept & Implementation & Digital Function

- Binary Concept,Baud rate,Languages,Protocols

- PLC Programming on PPM & Industrial Application

- I/O Mapping & Addressing

- PLC PC communication troubleshooting

- Latching & Unlatching Concept

- Uploading & Downloading Program

- Addressing of Memory Bits

- Timers

- Counters

- Compare Instructions

- Compute/Math Instructions

- Move/Logical Instructions

- Program Control Instructions

- Analog Scaling – SCP

- Programming Examples

- Introduction

- Difference between SCADA and HMI

- Introduction to SCADA Software

- SCADA Types,Tag Name & Tag Types

- Selection & Requirements of Components

- Creating Database of Tags

- Driver Configuration

- Animation Properties

- Introduction to Features

- Dynamic Representation

- Design of SCADA/HMI for various application

- Device Communication(PLC)

- Alarms

- Calibration

- Loop checking: Cold loop check , Hot loop check

- FAT, SAT

- IO Forcing and checking

- PLC program testing at site, SCADA screen testing

- Communiction check

- Signal Measurement

- Control panel IO testing etc

- Mock Interviews

- CV Preparation

What Our Students Have to Say About This Course

I was searching for training and I got reference to Empirical Technologies through my friend.

I found this training best in all way. Teaching is totally in practical approach.

Student signature after every topic completion and not to proceed for next topic till complete understanding. I personally liked this practice very much in this organization.

Ravindra Khade

Vedant Equip sales & Service Pvt. Ltd.

In this training institute you will learn whole project cycle and actual work activity of it.

Hands on experience in doing wiring , and actual PLC programming with field testing.

Total customization in training batch, syllabus.

This team gives technical support even if after course completion.

Bansidha Patil